Ngai Fung Industrial Co.,Ltd. is a production-oriented enterprise specializing in the design and processing of zinc and aluminum alloy molds, deep processing of zinc and aluminum alloy products, precision CNC processing, production, sales, and import and export trade. The company has nearly 40 years of experience in the production of hardware products and has an excellent team in product development and design, production processing, sales, and management.

We will serve our customers with the tenet of "diligence, sincerity, quality, and innovation", and strive to achieve "customer satisfaction and continuous improvement" to provide customers with high-quality and precise die-casting products and satisfactory services.

Company Founded in

Factory Area

Existing Employees

Zinc Aluminum Alloy Die Casting

Strictly follow IATF16949 international quality standard

Mold Processing and Manufacturing

Strictly follow IATF16949 international quality standard

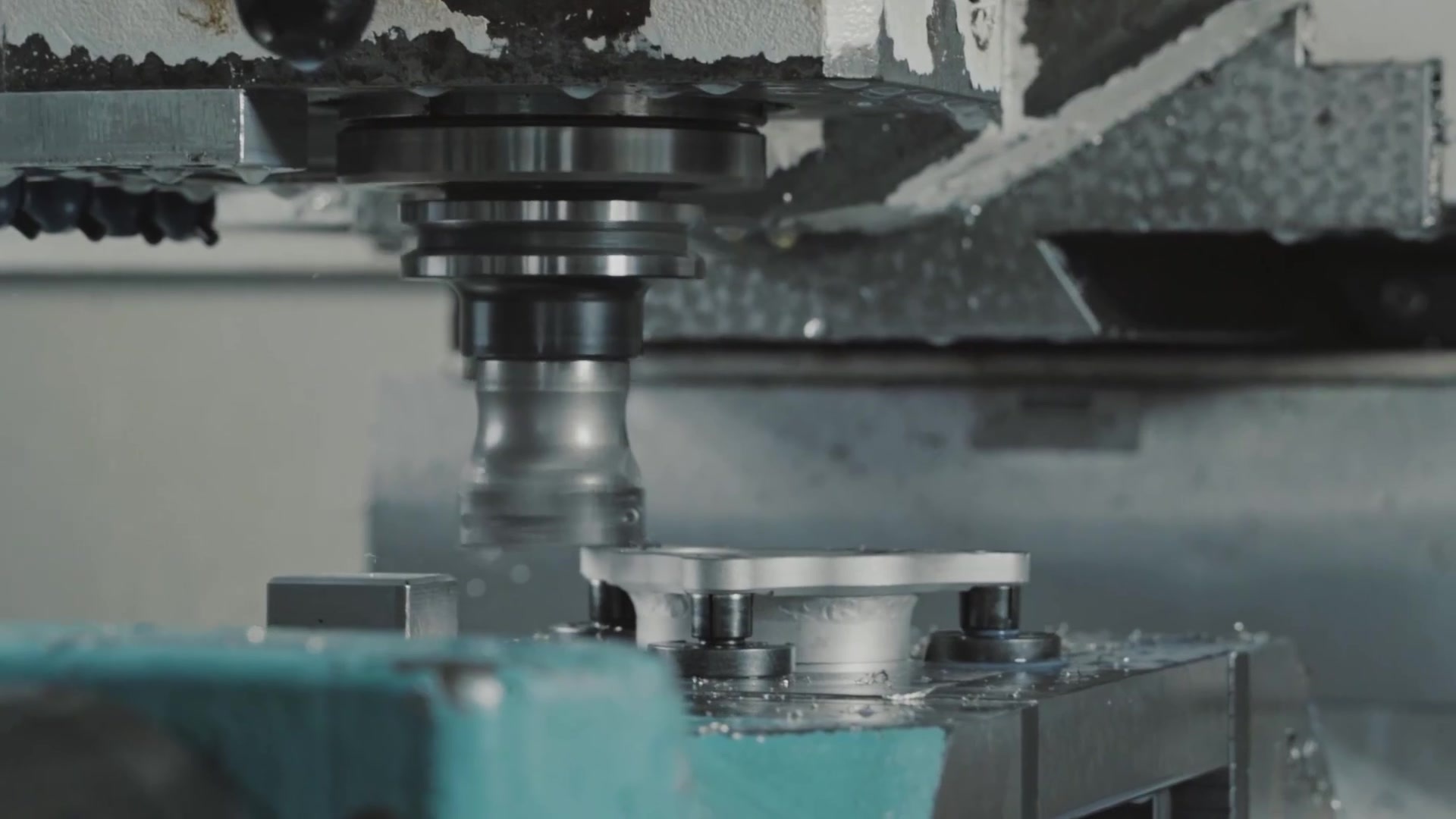

CNC Fine Machining

Strictly follow IATF16949 international quality standard

Electroplating and Spraying

Strictly follow IATF16949 international quality standard

Automation and Assembly

Strictly follow IATF16949 international quality standard

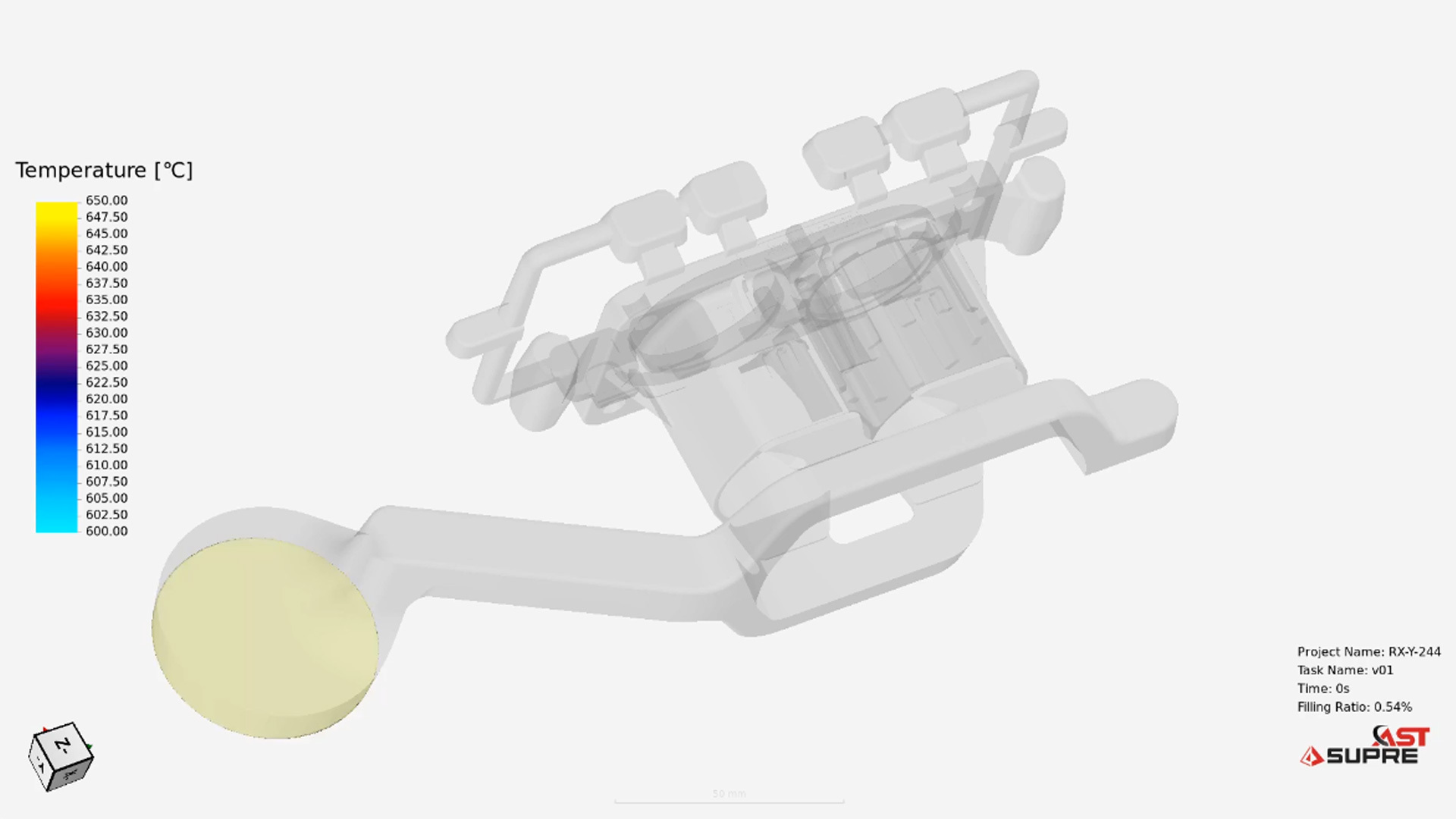

Precautions for the entire process of mold use and maintenance

Confirm that the parting surface is free of scratches (Ra≤0.8μm). Check that the ejector pin/slider moves smoothly (manual stroke test). Verify the patency of the cooling water channels (flow meter test, pressure drop ≤0.1MPa)

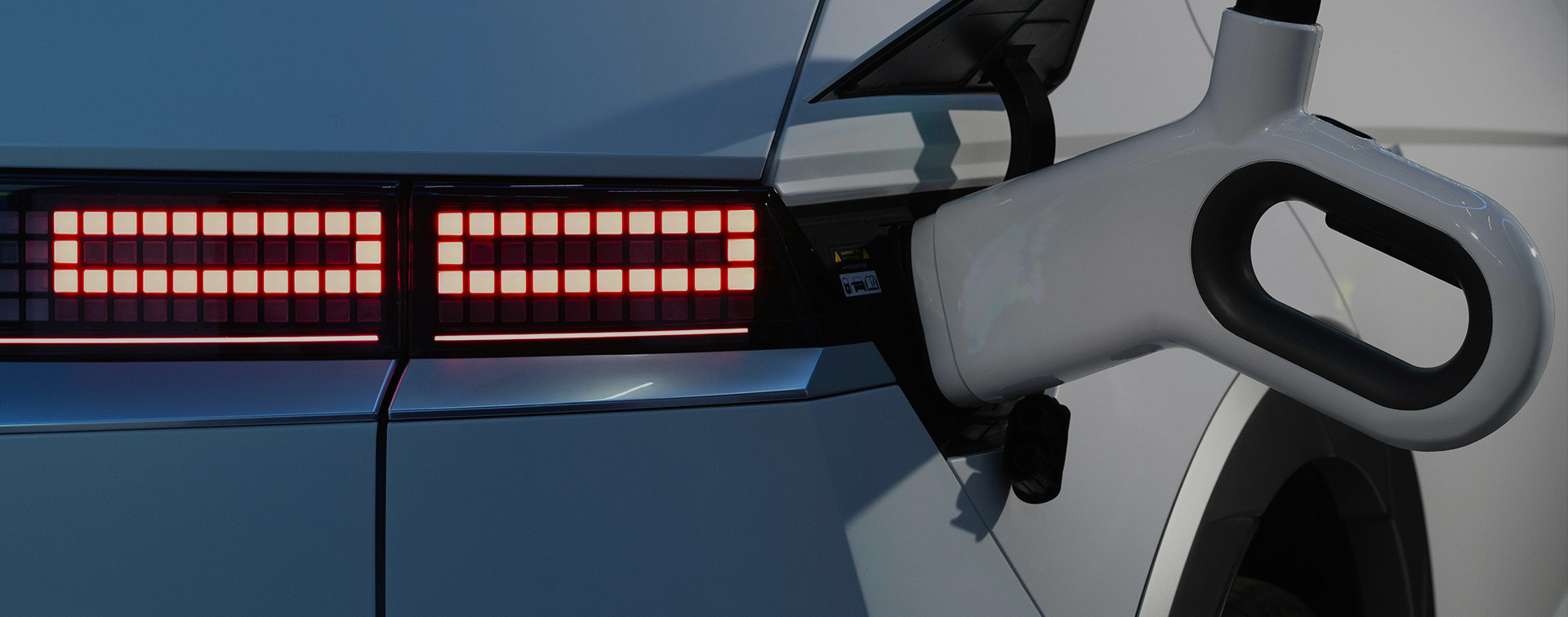

1. Automotive Manufacturing Electrophoretic coating: Cathodic electro-deposition (CED) film thickness 20±2μm, salt spray test 1000h without rust Topcoat spraying: Dupont waterborne color paint + 2K clear coat system (baking temperature 140℃/30min) Robot rotary cup electrostatic spraying (speed 50,000rpm, coating rate ≥85%)

Confirm that the power supply and pneumatic/hydraulic system are stable (voltage fluctuation ≤ ±10%). Check the lubrication status of the guide rails and lead screws, ensuring that there is sufficient lubricating oil (ISO VG32 or higher guide rail oil is recommended). Verify the rigidity of the fixture/tooling to avoid machining vibrations (torque wrench tightening and a bolt pre-tightening force error ≤ 5% are recommended).